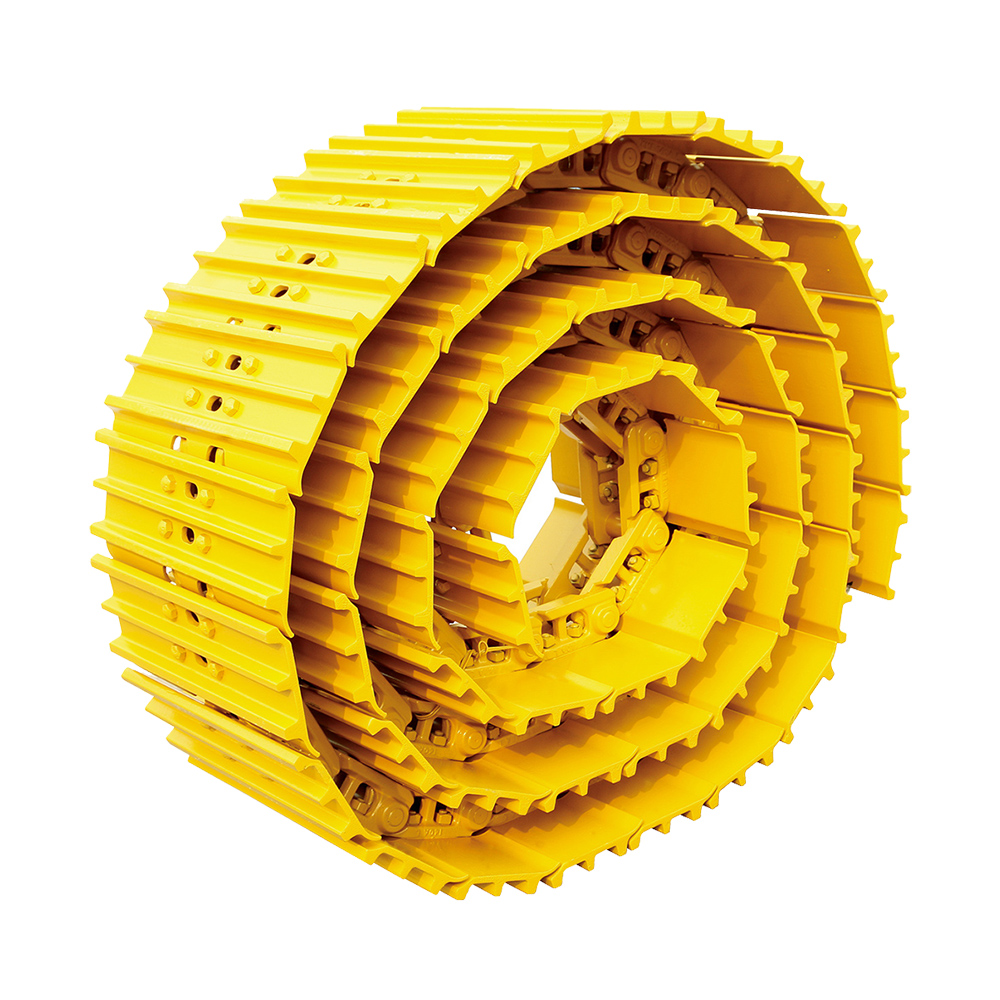

What is the difference between a bulldozer and an excavator Track link chain assembly Chain

The force on the excavator track link assembly chain is mainly longitudinal supporting force, and the working parts are concentrated in the big arm cylinder and bucket. Bulldozer is mainly walking work, its weight of more than 20 tons plus full load thrust is very large, It is mainly through the horizontal pull of the chain to make the vehicle walking work, so the general performance of the bulldozer chain is better than the excavator, Material quality is generally wear-resistant 3MnB steel forging. There is a gap between the weight and the cross section of the chain. It is a waste of the bulldozer chain when it is used on the excavator. It will take less than long for the excavator chain to be used on the bulldozer.The chain material is 35MnB forged, and the link and pin are 40Cr. Integral quenching and tempering heat treatment, internal and external medium frequency. Internal and external precision polishing finish up to 0.2 . All processes are processed by CNC vertical machining center. So as to achieve high precision, more wear-resistant, longer service life. After the assembly is completed, the finished product is shot blasted as a whole again. The appearance of the chain is made of advanced environment-friendly water-based paint with stronger adhesion, making the overall appearance more beautiful and high-end.What are the advantages of our bulldozer track link chain assembly

Track link chain assembly detail information

| Product detail information | |

| Description: | Track link chain assembly MINING OPERATION |

| Place of origin: | China |

| Brand name: | PT'ZM |

| Model number | D11 |

| Price: | Negotiate |

| Packaging details: | Fumigate seaworthy packing |

| Delivery time: | 7-30 days |

| Payment term: | L/C T/T |

| Price term: | FOB/ CIF/ CFR |

| Minimum order quantity: | 1 PC |

| Supply Ability: | 10000 PCS/month |

| Material: | 35MnB /40Cr |

| Technique: | Forging |

| Finish: | Smooth |

| Hardness: | HRC45-55 |

| Quality: | mining operation |

| Warranty time: | 1600hours |

| After-sales service: | Video technical support, Online support |

| Color: | Yellow or Black or Customer required |

| Application: | Bulldozer & Crawler excavator |